FuseRock PET-GF glass fibre 1KG spool 1.75mm

This product is currently out of stock!

Unfortunately, we have not been informed when the product will be available again. Enter your email address to receive a notification when the product is back in stock.

- Description

- Reviews

High-temperature Polyamide based with 15% chopped glass fibre reinforced FDM material.

Printing Tips:

- Recommended drying temperature: 80°C for 5 hours in a filament dryer or 90°C for 10 hours on the heat bed. Avoid exceeding 100°C to prevent spool melting.

Printing Setup:

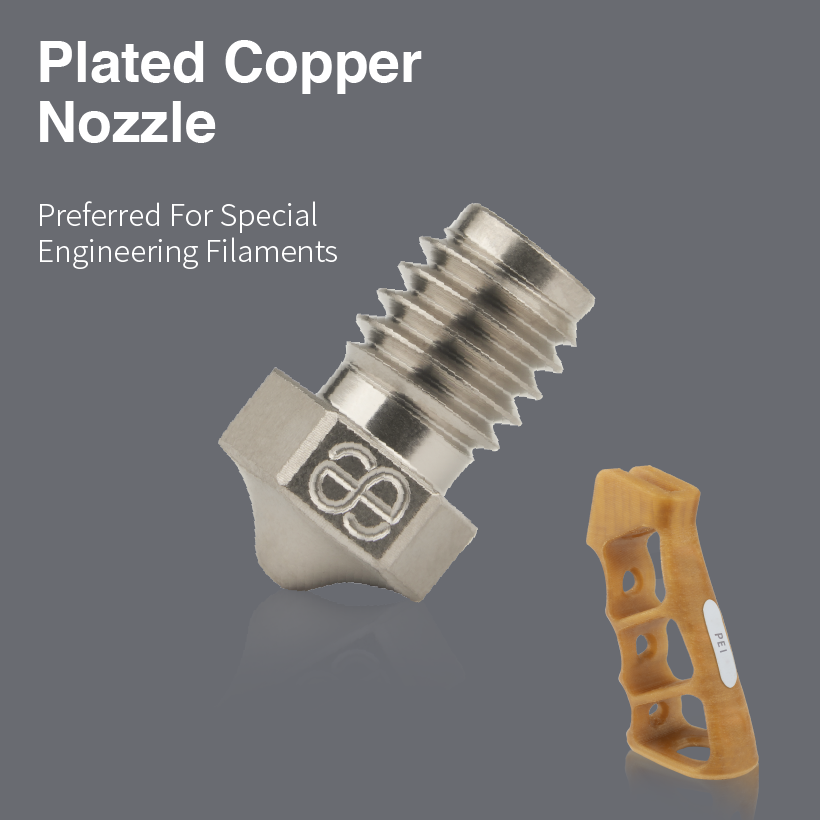

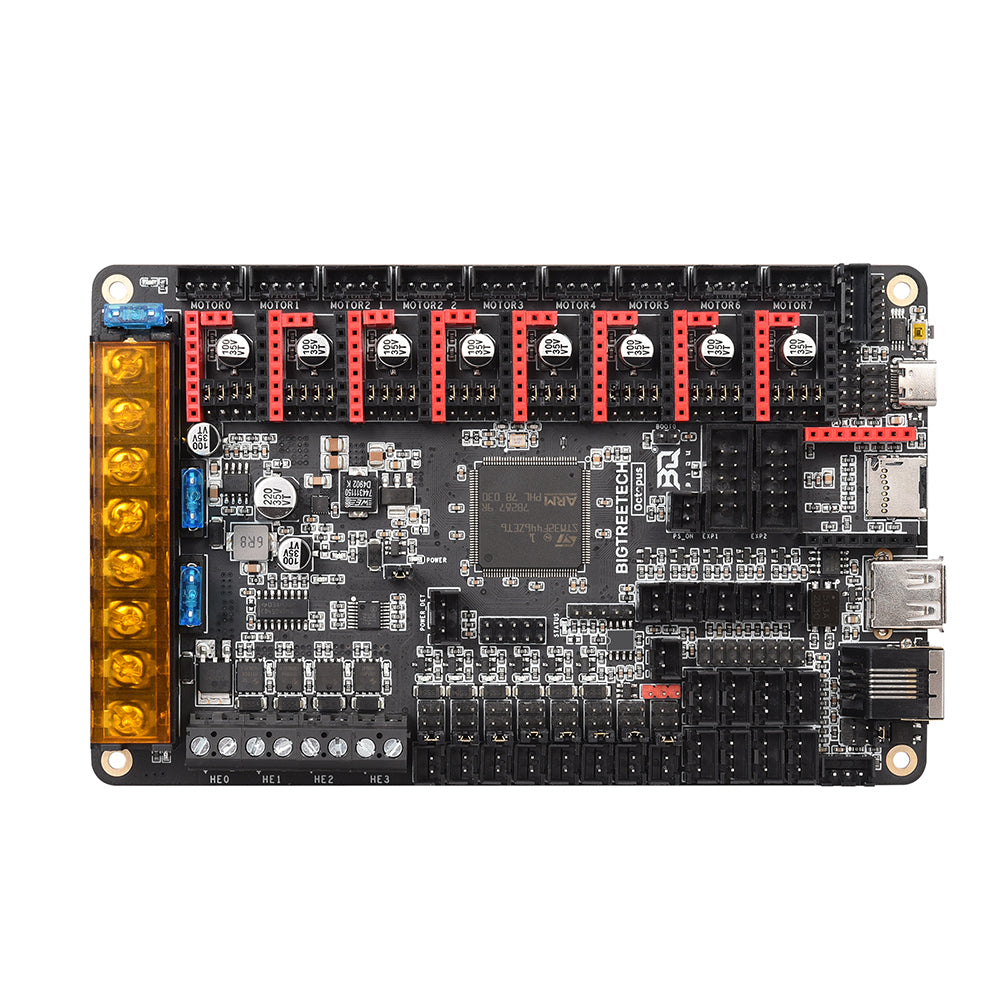

- Recommended nozzle: Tungsten Carbide / Hardened Steel.

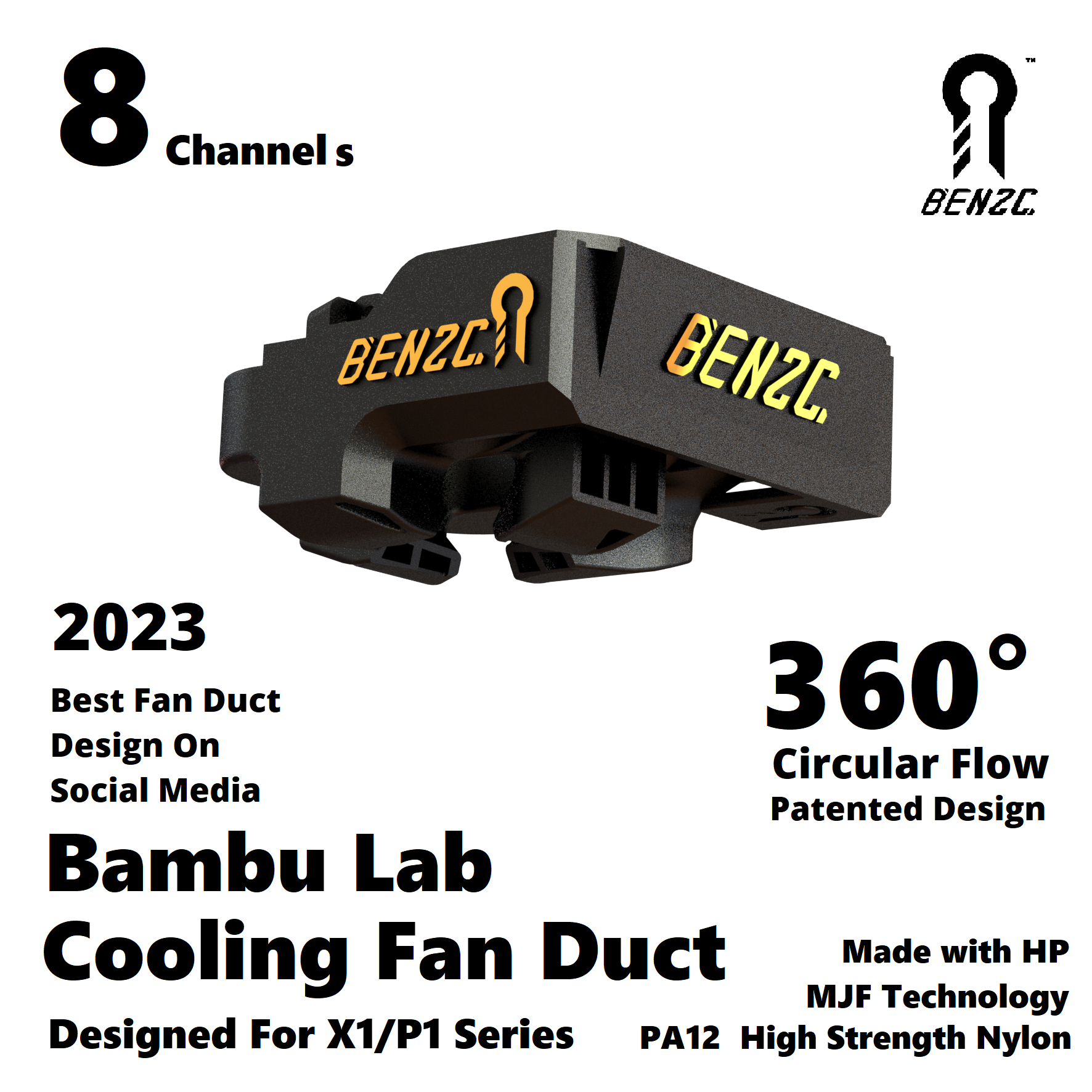

- Recommended printer: Enclosed printer.

Frequently Asked Questions

Q: What's the difference between PET-GF and PETG-GF? A: PETG-GF is reinforced with glass fiber and may contain glycol, resulting in improved transparency but reduced strength. PET-GF, on the other hand, refers to pure PET reinforced with glass fiber, providing greater strength and temperature resistance.

Q: How do PETG-GF and PET-GF differ in application? A: PETG-GF is versatile and suitable for everyday items, while PET-GF is a professional-grade material designed for complex and demanding environments.

Q: What is PET-GF used for? A: PET-GF is ideal for 3D printing functional parts in high humidity conditions, as well as mechanical assembly parts that require high temperature resistance and minimal warping.